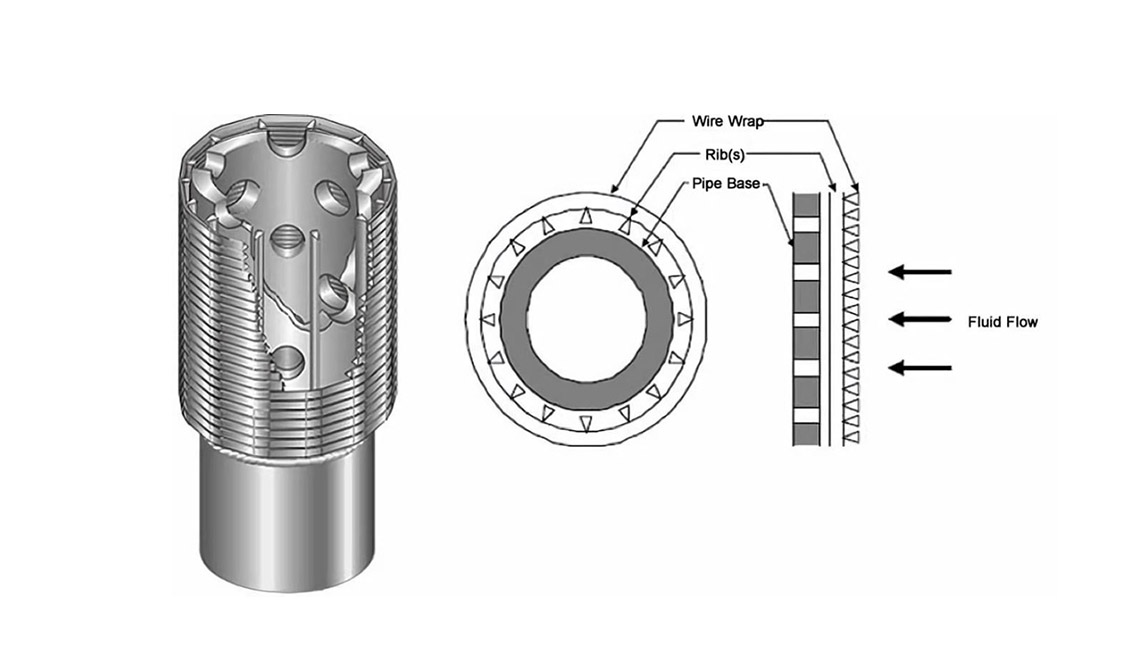

Wire Wrapped Sand Screen

WIRE WRAPPED SAND screen used in sand control applications to support the gravel pack. To form the screen, a profiled wire is wrapped and welded in place on a perforated liner. Screens are available in a range of sizes and specifications, including outside diameter, material type and the geometry and dimension of the screen slots. The space between each wire wrap must be small enough to retain the gravel placed behind the screen, yet minimize any restriction to production.

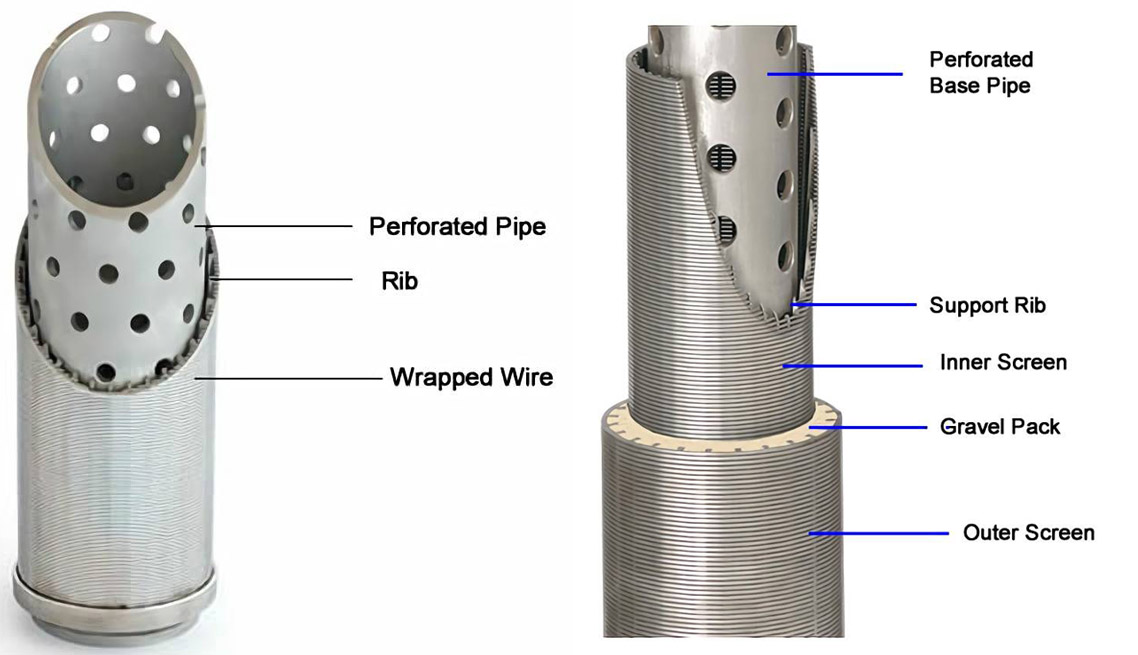

Pre packed sand screen contains perforated base pipe, inner and outer screen jackets and graded sand between the jackets. It is a modification of wire wrapped screen which is used in well sorted sand or stand-alone completion. Graded sand, with or without resin coating, is considered as a filter for reservoir particles.

Wire wrapped pre packed sand control screen is used in wells where conventional gravel packing is not feasible or economical. The thickness of gravel layer can be varied to meet special requirement.

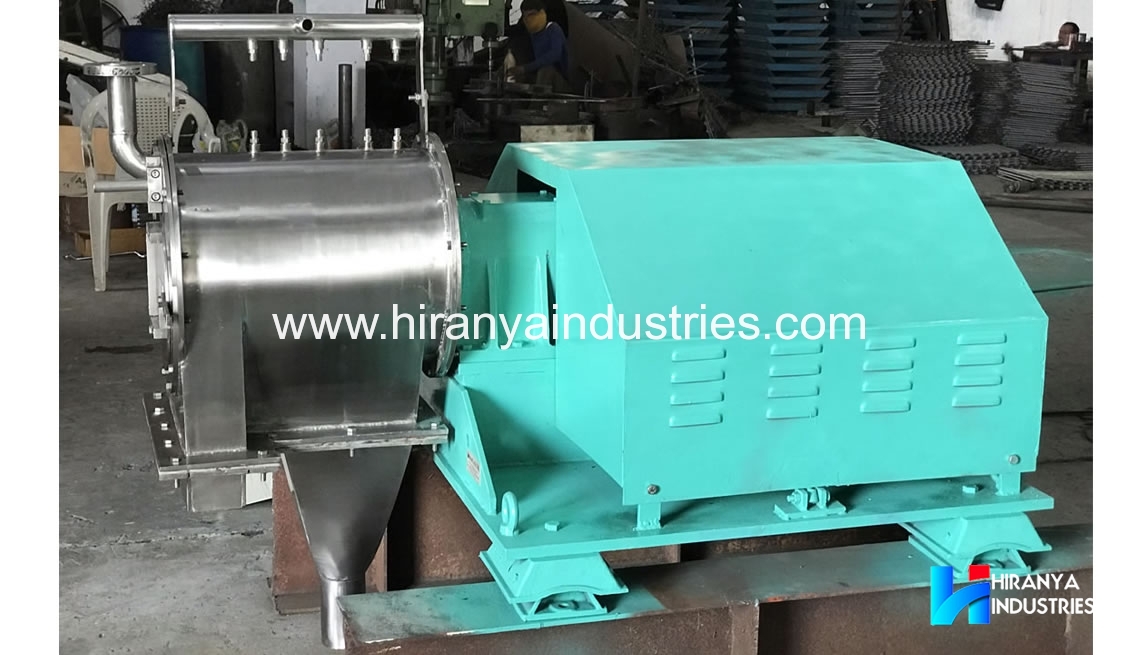

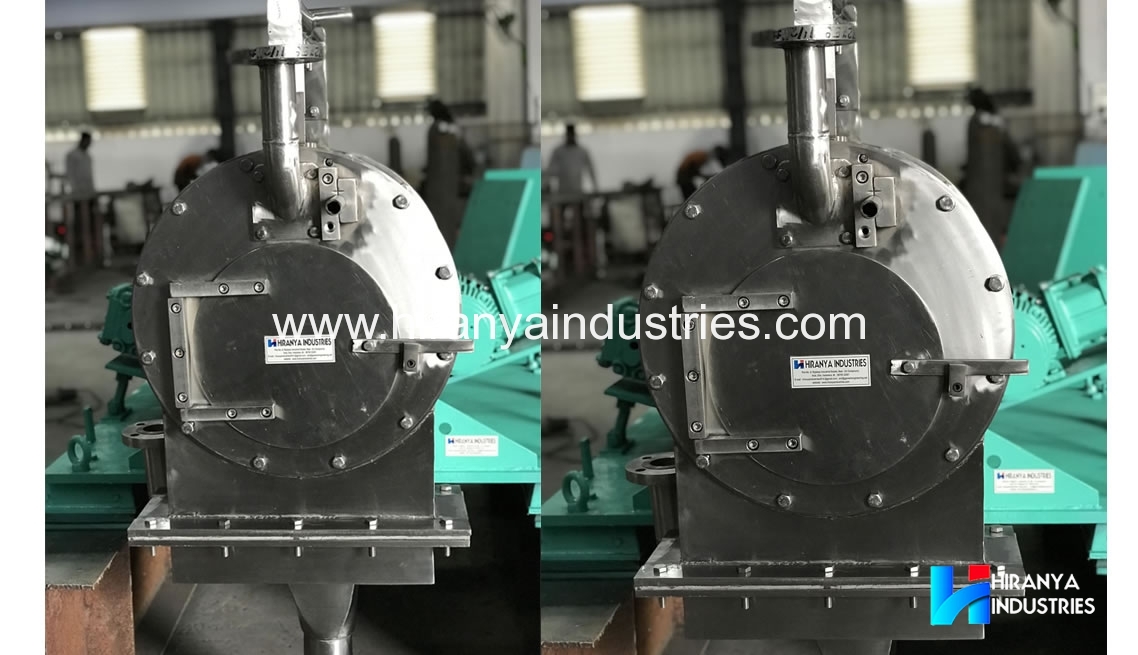

Pusher Centrifuge Machine

Hiranya Industries is involved in Designing, Manufacturing & Supply of Variety of Special Purpose Machines including Pusher Centrifuge for continuous filtering device used for solid-liquid separation used in diverse industry Sector for Bulk Chemicals, Pharmaceuticals, Mining and Minerals, Common Salt(Sodium Chloride)Agriculture and Food Industries, Plastic Processing, Fiber Industry etc.

We also supply all the necessary Spare parts and undertake Annual Maintenance Contract, Servicing, Repair work and conversion of Mechanical Model into Hydraulic.

TECHNICAL SHEET

- High Product quality &increased performance through proper selection of the Basket configuration, feed accelerator and Screen.

- Simple and easy maintenance through service-friendly design.

- Choice of drives: Mechanical and Hydraulic drives are available.

- Quick installation on Vibration dampers.

- Simple & continuous operation.

- High yields, throughput & wash efficiency.

- Low energy consumption.

- No spillage.

- Eliminates manual handling.

- Maintenance: simple & low-Cost.

- Less floor space requirement.

Solids collected on the screen and feed liquors drain through. The pusher plate rotates with the basket and reciprocates. On the forward stroke, the plate pushes solids along the screen, Consolidating the solids into a uniform cake.

On the reverse stroke, fresh screen is exposed and more slurry is deposited.

Cake dries as it moves along the length of the screen and wash liquor May be applied to remove impurities. Cake is pushed off the discharge end of the screen and directed to the Collection chute.

Main Applications

ABS, Ammonium Chloride, Ammonium Sulphate, borax, Common Salt, Cellulose acetate, Ferrous Sulphate,Dichlorobenzene, Hydroquinone, Hexamine, Nickel Sulphate, Lithium compound, Nitrocellulose, Potassium Carbonate, Potassium Chloride, Oxalic acid, Potassium Carbonate, Sodium Chloride, Sodium bicarbonate, Sodium Carbonate, Sodium Chlorate, Sodium Cyanide, Urea, and in general ANY Crystalline Inorganic salt.

- Process:Continuous

- Solid content: ˃25% by wt.

- Average particle size:80-2000µm

- Solid throughput:400 to 25,000kg/hr.

- Solids recovery: ˃98%

- MOC: Stainless steel, Special materials

- Product should be crystalline.

- Minimum particle size: 80 µm

- Maximum particle size:About 2000 µm

- Feed requirement: High solid content & uniform slurry concentration.

- Main Shaft & Pusher Shaft.

- Basket-1st& 2nd

- Sieves or Screen Segments.

- Pusher Hub & Pusher Plate.

- Front & Rear Bushes.

- Excluder Seals.

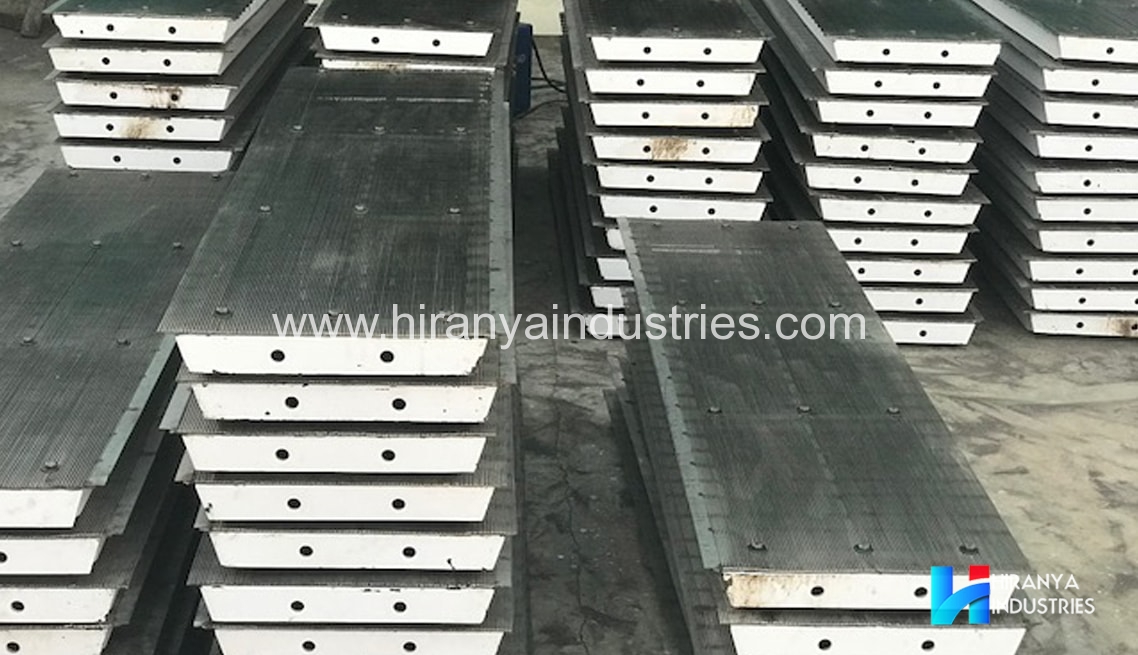

Cadres Frame

These cadre frames are specially designed for Solvent Extractor. This is fitted with the extractor chain. This is made from tested material. The various type of standardized are available for perfect Suitability.

As a leading manufacturer, we are indulged in manufacturing and supplying the durable range of Extractor Cadre Frame. Our experts have designed these products, especially for Solvent Extractor.

To manufacture these products, we are associated with trusted vendors to procure superior quality of raw materials. For perfect fitting, we offer these products in different model and design.

Looped / Welded Wedge Wire Screens

Hiranya Industries manufacturing looped and welded wedge wire screens. Now we are developing Hiranya Wedge Wire unique metal to metal welded wedge wire screen in V shape and loop screens wire is made from round wire which is first loop at regularly pitched intervals and then pressed into deep wedge shaped. The loops themselves are pressed so as to produce at each side accurately sizes spacing shoulders which but together when the wires are assembled. The width of the slot apertures in the finished panel is determined by the difference between the width of the top face of the wedge profile and the width over the spacing shoulders. In contrast the welded method a demand has grown for wedge wire assembled by welding. We have met this demand with the very latest in TIG welding technology to weld for wedge screen typical application areas.

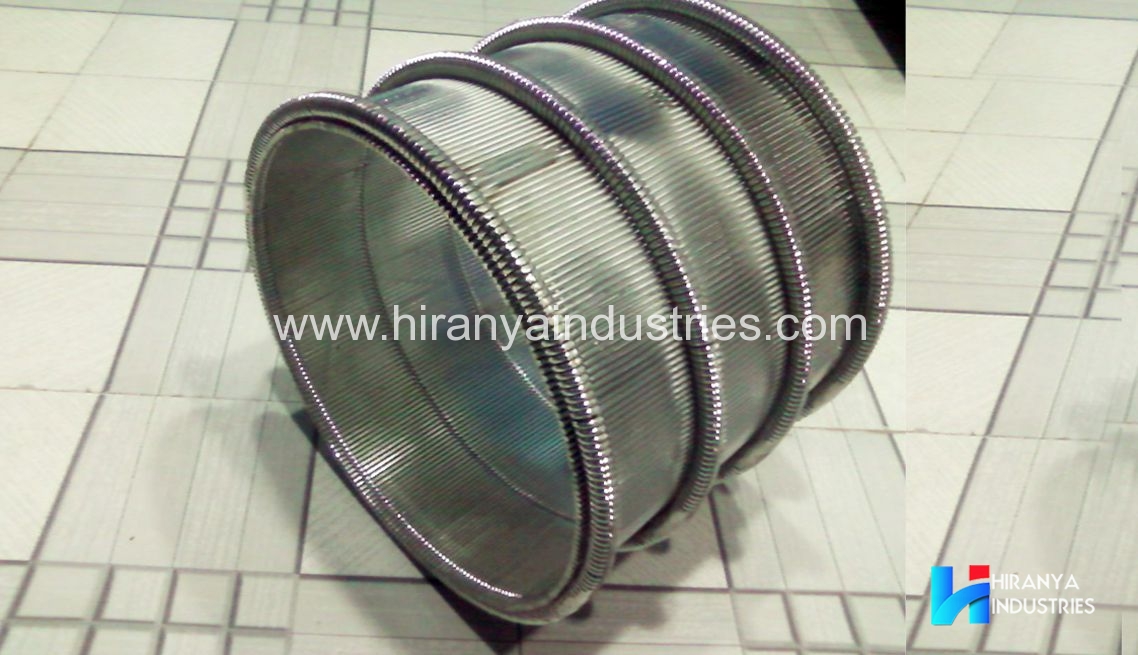

Pusher Centrifuge Basket

In addition to flat panels, wedge wires can be readily made up into full cylinders and segments of cylinders in most cases, the cross rode lie along the circumference and the profile wires lie parallel to the axis. Occasionally, this arrangement is reversed.

Very High efficiency basket are made from looped wedge wire and also made from metal to metal welded wedge wire in conical shape, Cylindrical shape and in double Cylindrical shape and pusher type centrifuge basket. The wedge wire baskets have clear advantage of very high filtration efficiency, longer life and accurate aperture over any other conventional screen baskets. We can manufacture in large sections, giving simple and speedy fitting, ensuring short down times greater free area, resulting in better dewatering and greater throughput. Conical and Cylindrical baskets can be tailor made to suit the customer requirement and maximum efficiency.

Flat Panels

Flat panels are the most widely used type of wedge screens mainly in the mineral processing both for stationery as well as vibratory decks. Flat panels are dependable for effective sizing or classifying as they have accurate bars spacing from as low as 0.01 mm to 4.5 mm at interval of 0.01 mm. Because of in looped construction they probably have the highest strength for any particular size and self supporting and do not require support for long distances.

Rotary Juice Screen

Hiranya Wedge Wire unique metal to metal welded wedge wire screen in V shape and loop Screens wire is made from round wire which is first loop at regularly pitched intervals and then pressed in to deep wedge shaped.

The loops themselves are pressed so as to produce at each side accurately sizes spacing Shoulders which but together when the wires are assembled. The width of the slot apertures in the finished panel is determined by the difference between the width of the top face of the wedge profile and the width over the spacing shoulders. In contrast the welded method a demand has grown for wedge wire assembled by welding. We have met this demand with the very latest in TIG welding technology to weld metal for wedge wire screen.

Hiranya Wedge wire has developed rotary screens complete with side flanges and support/drive drums of stainless still mainly for sugar and other chemical plants to achieve very efficient filtration. Our rotary screens have very strength coupled with very high open area and rigid construction. Rotary screen sizes from 1000 mm to 8000 mm long. Flow rates are depends on rotary screens open are and sizes .We will make a Rotary screen up to 6000 mm diameter.

- All type heavy industrial filters Looped &Metal to Metal welded wedge Screen

- 1000 TCD to 10,000 TCD capacity Juice Rotary Screen Machine, DSM Screen, Curved Screen

- Separate Welded Rotary drum as per your requirement

- Strainer and Welded & Looped Basket any size in 50 micron to 8 mm opening (Aperture).

Centrifuge Basket

Very High efficiency basket are made from looped wedge wire and also made from metal to metal welded wedge wire in conical shape, Cylindrical shape and in double Cylindrical shape and pusher type centrifuge. The wedge wire baskets have clear advantage of very high filtration efficiency, longer life and accurate aperture over any other conventional screen baskets. We can manufacture in large sections, giving simple and speedy fitting, ensuring short down times greater free area, resulting in better dewatering and greater throughput. Conical and Cylindrical baskets can be tailor made to suit the customer requirement and maximum efficiency.

Conveyor Wedge Wire Screen

We are making a wedge wire conveyor screen as per client’s requirement. Conveyor wedge wire screen particular use in food factory for receives the materials from feed hopper and transports at a pre determined speed from the feed end to discharge end.

The band conveyor moves over rails suitably located inside the Extractor and rides on specially constructed sprockets at other end. The speed of the band conveyor is easily adjustable within desired limits. An adjustable damper enables the regulation of height of bed of material on band conveyor.

Cylindrical Wedge Wire Screens

In addition to flat panels, wedge wires can be readily made up into full cylinders and segments of cylinders in most cases, the cross rode lie along the circumference and the profile wires lie parallel to the axis. Occasionally, this arrangement is reversed.